瀬戸焼は千年以上の歴史と伝統を有する日本を代表するやきものです。

この瀬戸焼の特徴は、中世期では唯一、釉薬を施した陶器を生産していた産地であり、

千年以上の間、様々な釉薬を駆使したやきものを作り続けてきました。

1.灰釉(かいゆう)/ 御深井釉(おふけゆう)薄い緑色/薄い青色

植物の灰を使用した釉薬。瀬戸焼発祥の時から用いられている伝統的釉薬であり、全ての釉薬の基本となる釉薬である。灰の中に含まれる不純物によって若干色調が変わるが、酸化焼成では淡い黄緑色、還元焼成では淡い青色を呈する。御深井釉とは、江戸時代、尾張徳川家の御庭焼として名古屋城下の御深井丸で焼かれていたやきものに用いられた釉薬に由来するもので、植物の灰を主原料としているもの。

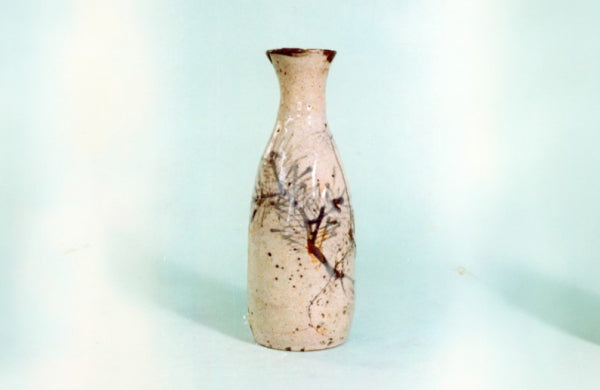

2.鉄釉(てつゆう)茶色、焦げ茶色、黒色

酸化鉄を呈色剤とした釉薬。瀬戸焼では、鎌倉時代の13世紀末期の「古瀬戸」に使用されたのがその最初である。その含まれる鉄の分量によって黄褐色から黒色まで発色する。瀬戸黒、天目釉、古瀬戸釉等も鉄釉の一種である。

3.黄瀬戸釉(きせとゆう)黄色

ごく微量の鉄分により黄褐色に発色する釉薬。桃山時代の16世紀末期に、瀬戸の陶工が美濃に移り住んで開発された釉薬である。装飾のアクセントとして緑色のタンパン(硫酸銅)を使用したものが多い。

4.織部釉(おりべゆう)/辰砂釉(しんしゃゆう)緑色/赤色

酸化胴を呈色剤として緑色に発色する釉薬。千利休の高弟である古田織部が好んだことからこの名が付いた。桃山時代の17世紀初期に、瀬戸の陶工が美濃に移り住んで開発された釉薬である。銅は酸化焼成すると織部の緑色に発色するが、還元焼成すると赤色に発色する。

5.志野釉(しのゆう)白色

長石を中心に使用した釉薬で、光沢し白濁した白色に発色する。桃山時代の16世紀末期に、瀬戸の陶工が美濃に移り住んで開発された釉薬である。

6.青磁釉(せいじゆう)青色、緑色

微量の酸化鉄により青色または緑色に発色する釉薬。瀬戸では、江戸時代後期の19世紀初期に磁器の製造が始まった時から使用され始め、特に明治時代以降盛んに使用されている。クロムを使用したクロム青磁も瀬戸では多用されている。

7.瑠璃釉(るりゆう)紺青色、藍色

呉須、コバルトにより紺青色に発色する釉薬。瀬戸では、江戸時代後期の19世紀初期に磁器の製造が始まった時から使用され始めるが、高価な呉須を多量に使用するため、尾張藩から一時製作が止められたことがある。特に明治時代以降、火鉢や植木鉢等に盛んに使用されている。